Updated October 20, 2000

This is the proposed layout (revision no. 2,348 or so!) of my instrument panel. The bottom piece, below the heavy line, was actually going to be folded back to form a stiffener/hem but due to the inherent stiffness of the metal that the panel is made out of the flange wasn't done. The dashed line along the upper edges represents the line of the foam top deck behind the panel. Instruments are all standard stuff; the airspeed is a small (i.e. cheap) unit reading up to 120 MPH. I have a single Westach CHT/EGT and a Westach tach/hour meter which runs off the magneto (I have no electrical system). I wanted an hour meter, but all the Hobbs types I looked at need electricity. I had Westach add range markings on the tach for my 1835 VW. The fuse just to the right of the tach is for the tach itself (Westach recommends a fuse). Westach recommends keeping this tach away from the mag compass, which is why I tried to keep them as far apart as possible.

Oil pressure and temp. are mechanical units. Along the bottom are choke, mixture, cabin air and cabin heat. My mag switch is at far left. I have a small slide-open window within the port side forward window, allowing me to reach in and operate the choke, mixture, mag, and throttle through the window while prop-starting the engine. Remember, the VW rotates CCW as you look forward, so standing at the port side of the airplane behind the prop, I pull the prop through with my left hand and operate the controls with my right, through the window.

I've left space in the center of the panel for mounting a handheld COM (an Icom IC-A4 Sport, which actually doesn't look like the image), and maybe my handheld GPS (Magellan GPS 2000)just to the left of it, if it'll work there.

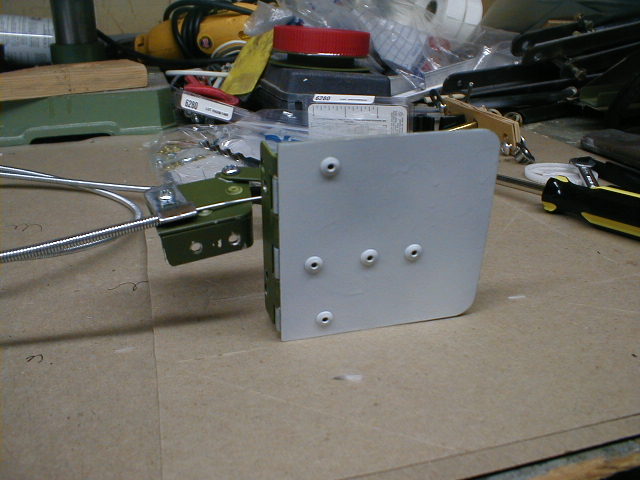

The panel is made of .062" 6061-T6 aluminum, cut using waterjets (see website at www.waterjet.net , Carmin Industries. It came out terrific!

Now I'm ready to work on the cabin air and heat controls, pitot and static tubing, wiring, etc.

Return to My Flying Squirrel Home Page